Precision for the Planet – European engineering excellence in the Sentinel-5 optical payload

When it comes to environmental and climate data from space, every photon counts. The Sentinel-5 mission of the European Space Agency (ESA) is designed to continuously monitor the Earth’s air quality – providing vital insights for science, policy, and environmental protection. Such a task demands the highest levels of precision, stability, and reliability – qualities that define Europe’s approach to optical and mechanical space engineering.

Optical payload for global Earth observation

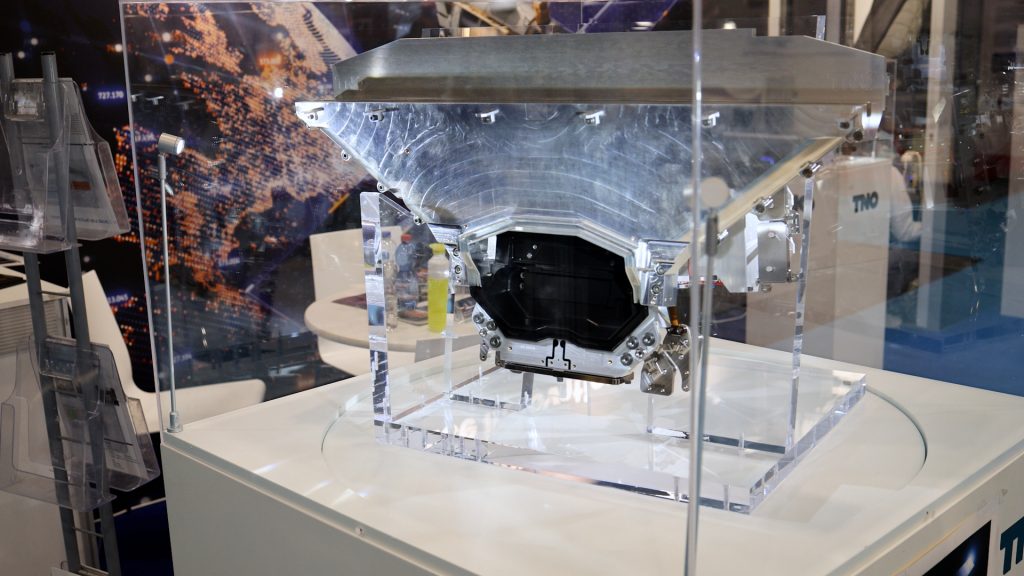

André Hoogstrate, Senior Research Engineer Optics Manufacturing at TNO Delft, explains that the displayed Sentinel-5 mock-up serves as a mechanical validation model for the overall concept. It is an optical payload demonstrator that replicates the key functions of the actual instrument – from light guidance to mechanical structure.

“It’s an optical payload designed to measure the air quality and pollution of the world,” Hoogstrate said. The instrument looks back at Earth through a 3,000-kilometer-wide field of view, detecting atmospheric gases such as ozone, nitrogen dioxide, and methane. The satellite travels in a polar orbit from the North to the South Pole, scanning the entire planet once per day.

The mock-up presented at Space Tech Expo Europe 2024 is used for mechanical, thermal, and optical validation: How stable is the structure under vibration and thermal load? How precisely can optical components be aligned and fixed? Such tests are essential before a system can be qualified for space.

From laboratory to hardware – engineering with a Hi-Rel mindset

Developing instruments like Sentinel-5 requires more than simulation. European research teams transform concepts directly into flight-ready hardware, combining expertise in precision optics, fine mechanics, and advanced manufacturing. Each component – whether optical bench, mirror mount, or thermally isolated interface – must meet ESA’s requirements for stability, mass, and lifetime.

Long-term stability is critical in Earth observation. Even minimal deformation can misalign the optical system and distort measurements. This is why the principles of Hi-Rel engineering apply across the entire process: material control, precision machining, strict tolerances, and thorough documentation.

These same principles are reflected in the work of companies like MSA Components. In space electronics, reliability and repeatability are equally essential. Whether optical structures or electronic assemblies – both must operate flawlessly in orbit for years. The shared goal: reliability as a system principle.

European collaboration for space-qualified precision

Sentinel-5 is part of the European Copernicus programme, symbolising the strength of joint development across Europe. Research institutes, technology providers, and specialized manufacturers contribute to missions that require extreme precision and endurance. This collaboration ensures Europe’s ability to independently design and deliver complex space systems – from concept to qualification.

The focus is always on reliability, accuracy, and scalability. Only when mechanical, optical, and electronic systems work in harmony can we capture the environmental data that science and policy depend on. Sentinel-5 stands as an example of this fusion of technology, precision, and purpose.

Looking back – and ahead

In Part 1 of our TNO feature, optical precision was also at the forefront – through the example of the Winston Cone, which produces uniform light for calibration purposes. While that demonstrator highlighted the role of optical calibration, the Sentinel-5 mock-up shows how research and design evolve into real flight hardware. Together, these topics illustrate the breadth of European expertise – from optical development to complex satellite instrumentation.

Despite their differences, both showcase one shared foundation: precision as a guiding principle. Whether in calibration units or optical payloads, European engineers combine scientific excellence with practical implementation – a hallmark of European engineering in orbit.

Looking forward

European Earth observation and science missions continue to demonstrate the power of collaboration. New projects with ESA and industrial partners show how the interaction of research, manufacturing, and Hi-Rel quality keeps advancing. For companies like MSA Components, this means continuing the dialogue between mechanics, optics, and electronics – united by one goal: precision for the planet.

Visit us at the Space Tech Expo Europe 2025

As in previous years, we at MSA Components will be exhibiting at Space Tech Europe. We look forward to engaging with our customers and partners to discuss upcoming missions, qualification needs and custom solutions for next-generation spacecraft and the space industry. Please visit our stand to meet us in person and discuss your projects and challenges, and find out how MSA Components can support you with the latest technological innovations on the market.

You will find us at booth number F11.

Of course, you are welcome to schedule an appointment with us beforehand.