• Energy storage, smoothing, filtering

• Applied standards : ECSS-Q-70-02, MIL-STD-202, DO-160

• ESCC 3201/009 versions upon request

• Materials meet UL94-V0 rating

• Suited for IR and vapor reflow soldering

• Frequency range up to 1 MHz

• Operating temperature range : - 55 °C to + 125 °C

• Weight : 3.2 grams

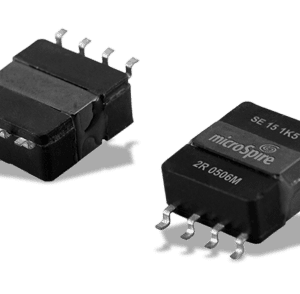

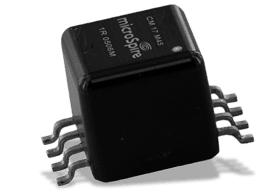

SESI 14SR SMD Power High Reliability Inductors

Microspire

QPL Component

SESI 14SR series are usually installed on Military applications and breadboards for Space applications.

Since January 2003, Microspire has been manufacturing Radio Frequency Fixed Coils, SESI 14SR series fulfilling

ESA ESCC Generic specification N° 3201 and detail specification N° 3201/009.

This qualification approval includes final production tests Chart II, burn-in and electrical measurements to testing

level B Chart III and qualification testing Chart IV.

For procurement, different quality levels are offered :

Since January 2003, Microspire has been manufacturing Radio Frequency Fixed Coils, SESI 14SR series fulfilling

ESA ESCC Generic specification N° 3201 and detail specification N° 3201/009.

This qualification approval includes final production tests Chart II, burn-in and electrical measurements to testing

level B Chart III and qualification testing Chart IV.

For procurement, different quality levels are offered :

• Final production tests Chart II

• Burn-in and electrical measurements Chart III with level B or C (as required)

• Lot acceptance testing Chart V if required

• Burn-in and electrical measurements Chart III with level B or C (as required)

• Lot acceptance testing Chart V if required

Components delivered through this specification need to be processed and inspected in accordance with the

Microspire Process Identification Document (P.I.D.).

Each component delivered is traceable to its production lot.

The terminal material and finish shall be brass, plated with 2 to 4 μm of Nickel, the finish shall be either Sn60Pb40

or Sn90Pb10.

Microspire Process Identification Document (P.I.D.).

Each component delivered is traceable to its production lot.

The terminal material and finish shall be brass, plated with 2 to 4 μm of Nickel, the finish shall be either Sn60Pb40

or Sn90Pb10.