Robotic Systems for Lunar Missions: Technical Insights Based on the DFKI Interview

MSA Insights. Based on our conversation with Dr.-Ing. Mehmed Yüksel and Manuel Meder from the Robotics Innovation Center at the German Research Center for Artificial Intelligence (DFKI).

Hybrid Rovers and Modular Space Robotics: DFKI Experts on Future Lunar Exploration

At Space Tech Expo Europe 2024, we spoke with two leading developers from DFKI. Three primary themes emerged clearly: rovers require adaptable locomotion to navigate difficult terrain; standardized interfaces accelerate missions and enable modular ecosystems; and autonomy is gaining importance because planetary environments demand decision-making close to the hardware.

Dr.-Ing. Mehmed Yüksel and team lead Manuel Meder demonstrated how these building blocks are realized in current systems and how research is progressing. The interview reveals which technologies already exist in laboratories and field tests, and how they may influence mission architectures in the medium term.

Hybrid Locomotion: The SherpaTT Rover as an Example

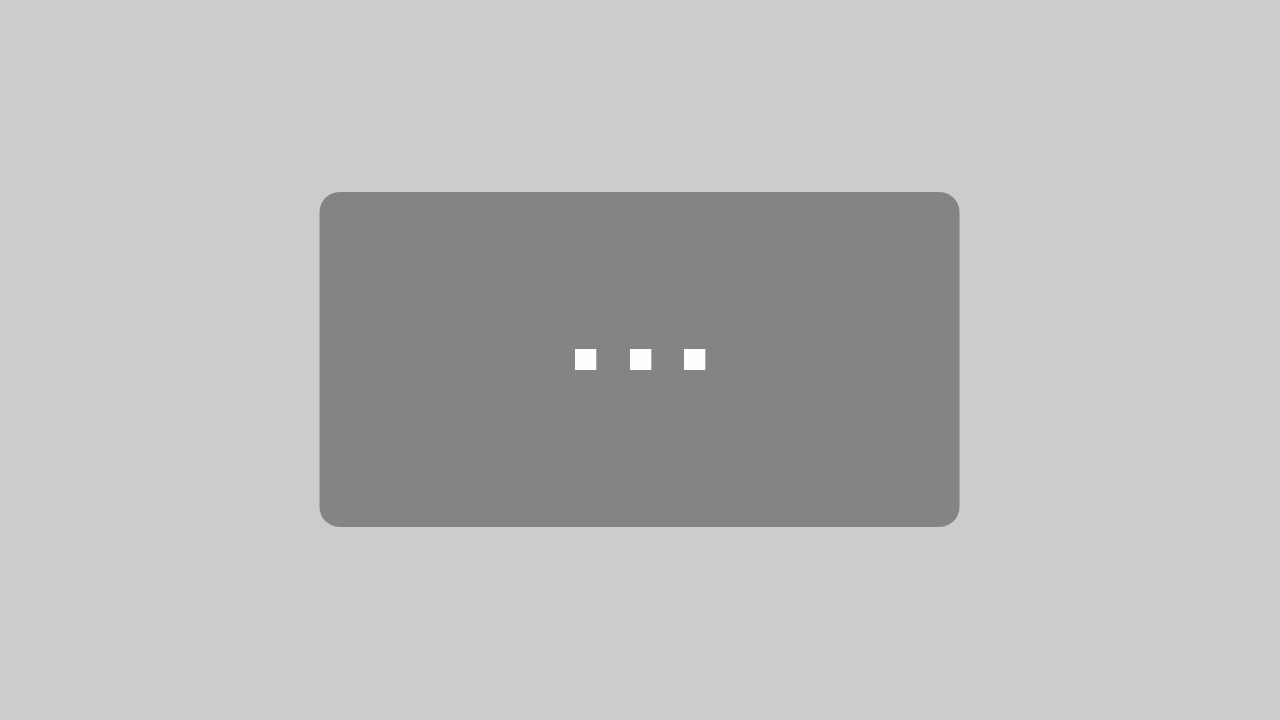

SherpaTT combines conventional wheels with actively controlled wheel-arms. This allows the rover to adapt its footprint, overcome obstacles, or move through tight passages. It can switch between a stable, four-legged stance, efficient driving and well-balanced climbing motions. SherpaTT's ability to articulate or lift individual wheel-arms helps it distribute load peaks more effectively in rocky or sandy terrain. This reduces impact forces on the chassis and prevents situations in which traditional drive systems might become stuck or tip over.

From an external perspective, this design illustrates how planetary mobility is evolving. Research groups worldwide are developing systems capable of responding dynamically to different modes of movement. Such adaptability is becoming increasingly important. Technologies like SherpaTT are regarded as forward-looking solutions that reduce mission risks and enable access to challenging terrain.

This flexibility places significant demands on the component level. Actuators, gear assemblies, thermal interfaces, harnesses and damping elements must withstand highly variable forces, frequent changes in direction, shifting contact points and complex temperature cycles. Sensor systems and data paths must remain stable even when their physical orientation changes significantly.

The combination of mechanical adaptability and modular expandability makes SherpaTT an example of how future rovers may be designed - not as rigid vehicles, but as versatile platforms that can adapt to different tasks and environments. This trend directly affects the selection, qualification and integration of hi-rel components.

Interface Architecture for Modular Robotics

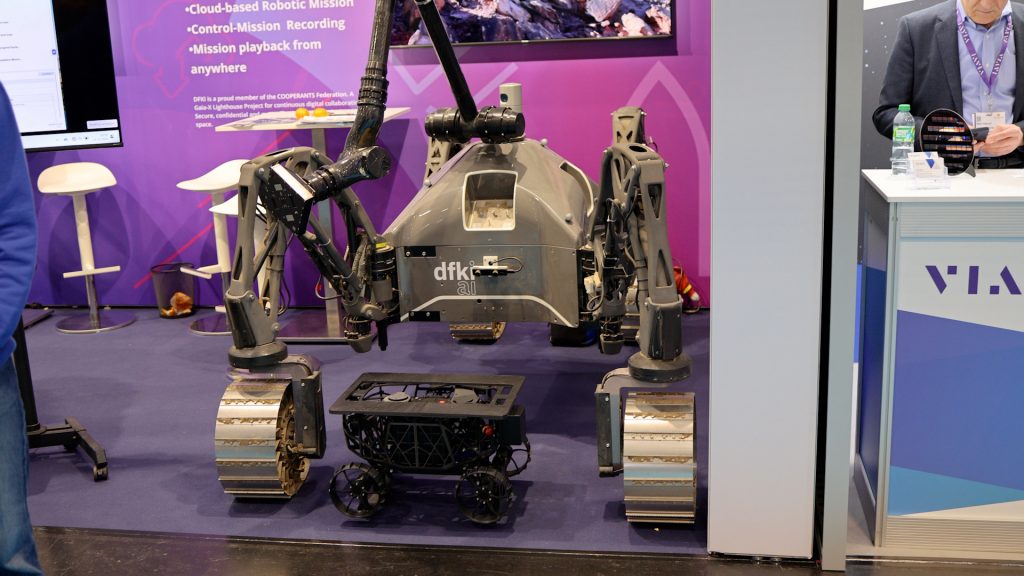

In the systems presented by DFKI, the EMI interface serves as a common connection point for tools and sensors. A single interface provides mechanical attachment, power supply and data communication. This enables modules to be mounted or exchanged with minimal effort - a level of modularity rarely seen in planetary robotics until now.

SherpaTT and the smaller COYOTE rover both use EMI in several variants to support sensors, manipulators or auxiliary energy units. In both cases, the benefits of a standardized interface become evident. A rover can switch tools without reconfiguring the underlying system architecture. At the same time, this approach allows future modules of varying maturity levels to be integrated - a key advantage for multi-partner mission concepts.

From an external technical perspective, the importance of such interfaces cannot be overstated. Studies on robotic exploration missions show that moving from customized solutions to interoperable standards is a major step toward reducing mission costs and shortening development cycles. An interface like EMI enables module reuse across projects, creates synergies across platforms and provides component suppliers with clearer mechanical and electrical requirements.

An electromechanical interface such as EMI requires the highest precision in contact alignment, locking mechanisms, electromagnetic compatibility and thermal resilience. Since rovers traverse uneven terrain and experience significant vibration, the connection must remain stable without intermittent contacts, data losses or drops in power delivery. Material selection, sealing concepts, connector durability and the ability to handle both low signal levels and high current loads reliably are equally critical.

EMI is therefore not simply a mechanical attachment point, but a central element in building modular robotic systems. The interview shows how far this development has progressed and how such interfaces may shape future mission architectures.

Autonomy and System Integration

The interview made it clear that hardware, electronics, software and AI at DFKI are tightly integrated. These systems are not separate subsystems but coherent architectures in which mechanical structures, power paths, sensor perception and data-driven decision-making are planned together from the outset. This level of integration distinguishes modern robotic platforms from traditional space systems, where subsystems were often developed independently.

Autonomy is not considered an add-on, but the foundation of the entire system logic. It must function locally so that rovers and small exploration units can operate reliably despite limited bandwidth or multi-second latency. Decisions regarding navigation, stability or energy management therefore take place where the data originates - directly within the hardware, close to sensors and actuators.

This architecture places stringent demands on sensing, power distribution, diagnostics and data integrity. Sensors must deliver accurate readings even during strong vibration or rapid changes in orientation. Power paths must be designed to manage load spikes caused by hybrid locomotion. Diagnostic functions must detect faults early, as remote intervention is usually delayed. Data paths must remain deterministic and robust so that autonomous algorithms can operate safely.

From an external perspective, this approach illustrates that future planetary robotic systems will rely increasingly on tightly integrated, end-to-end architectures. Components are no longer isolated parts but elements of a highly sensitive functional chain. For suppliers, this means that material robustness, electrical stability, EMC performance, contact reliability and resilience against dust, thermal cycles and mechanical stress directly influence overall system performance.

Energy and Thermal Concepts for Long Lunar Nights

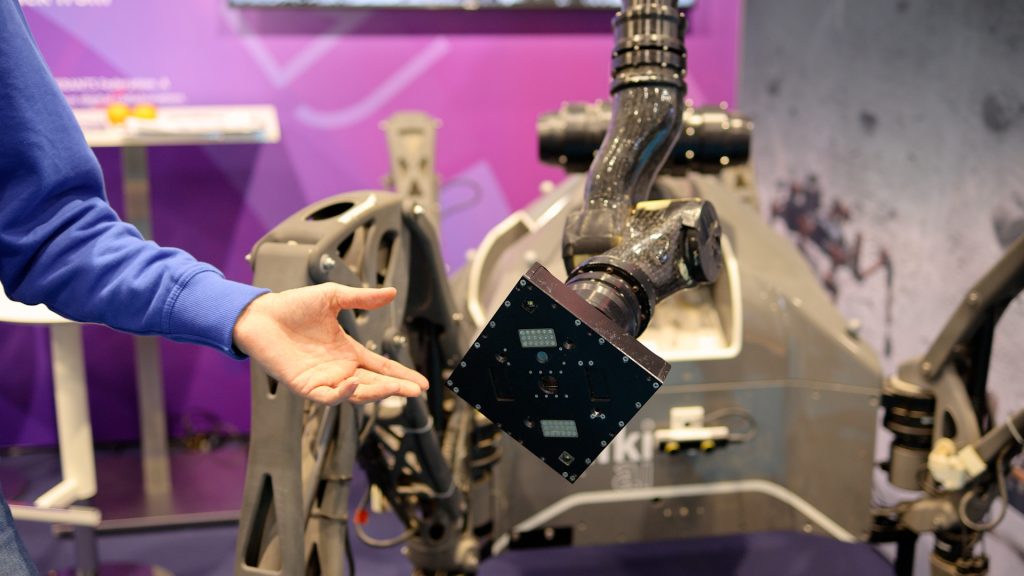

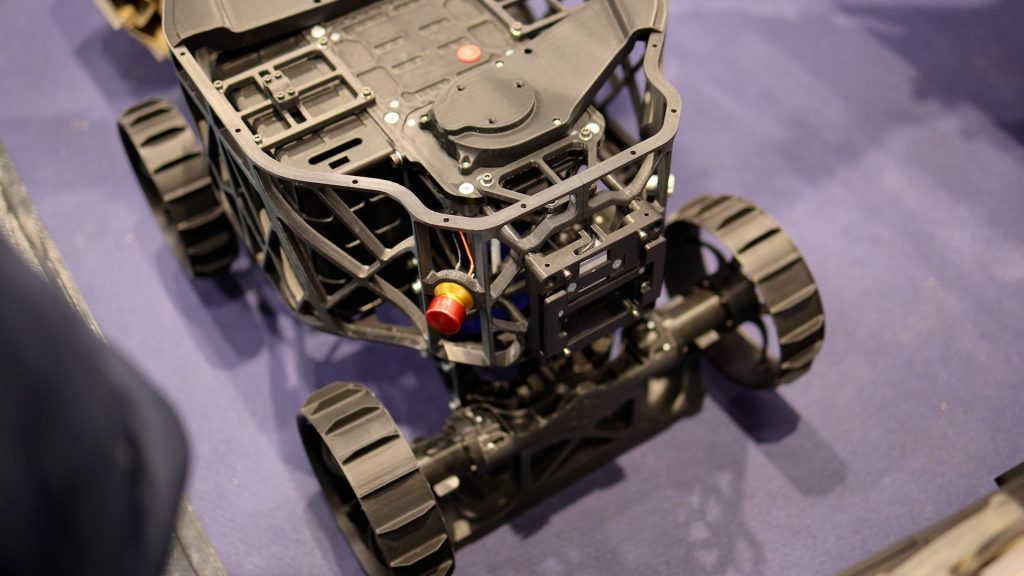

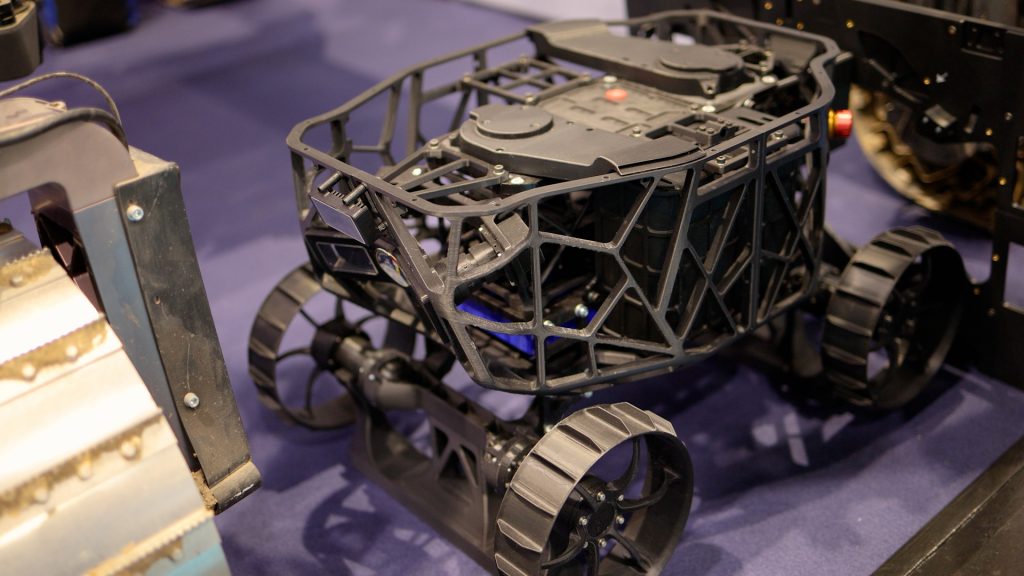

One of the most striking parts of the interview was the introduction of the "Sammler KI" rover demonstrator. It was designed to withstand the extended lunar night, during which temperatures fluctuate dramatically and no solar energy is available. The internal frame protects sensitive control and communication electronics from thermal and mechanical stress. The two battery types serve distinct roles: one powers mobility, while the other supports thermal regulation to keep critical components within their functional temperature range during the long dark phase.

A central radiator on the upper section releases excess heat when sunlight returns or when active components generate heat. Once solar radiation becomes available again, the solar panels gradually recharge the system. This architecture makes it clear that optimizing individual subsystems is insufficient. Power generation, thermal insulation, heat dissipation and battery behavior must be precisely coordinated.

From an external viewpoint, the Sammler KI concept highlights how demanding the lunar environment truly is. Prolonged periods of darkness pose significant risks, including thermal contraction, material fatigue, shifting electrical characteristics and the challenges of extremely low temperatures. Material selection, insulation, contact stability, battery chemistry and conductivity become mission-critical factors rather than secondary considerations.

At the same time, a broader trend in international research becomes evident: long-duration autonomous missions require robust energy storage, sophisticated thermal management and interfaces that remain reliable under extreme temperature cycles. From a component perspective, requirements for durability, tolerance ranges, aging behavior and resistance to both mechanical and electrical stress continue to increase. Sammler KI is a clear example of how future mission architectures are shaped by the physical realities of the lunar environment.

Field Testing in Analog Environments

SherpaTT has been tested outside the laboratory in Morocco, Utah and Lanzarote. These regions are established analogs for Martian and lunar terrain, combining loose regolith-like surfaces, sharp basalt structures, slopes and significant temperature variations. Such environments create real-world load cases - traction, vibration, thermal cycling and dust abrasion - that laboratory simulations can only approximate.

According to studies from ESA, DLR and other international research institutions, testing in these settings is essential for validating navigation strategies, analyzing material behavior in abrasive dust conditions and determining the long-term resilience of interfaces such as EMI. These experiments provide important insights into how robotic systems perform in natural environments and where modifications are needed for harsh planetary conditions.

Technical Conclusions from the Interview

The interview highlights several developments that will influence future mission design:

- Flexible mobility is essential for navigating complex planetary terrain.

- Standardized interfaces accelerate integration and increase reusability.

- Autonomy is becoming a strategic requirement for safety and efficiency.

- Thermal and energy design determines mission duration and operational depth.

Together, these points illustrate a clear trend: planetary robotics is evolving into a modular, interoperable and highly integrated system landscape. For research institutions, industry partners, integrators and component manufacturers, this creates both new priorities and new opportunities for specialized solutions.

Perspective from MSA Components

MSA has supported space-qualified components for many years and has observed how requirements shift as technologies evolve. The systems presented in the interview show that future missions will rely increasingly on integrated, modular and energy-intensive architectures. From our perspective, this creates clear technical priorities: reliable power distribution, robust connectors for variable load profiles, materials resistant to thermal cycling and stable data paths for autonomous functional chains.

The boundary between research and industry is becoming closer. System developers require components that integrate seamlessly into modular interfaces such as EMI, withstand wide temperature ranges and tolerate the mechanical stresses of hybrid locomotion. For MSA, this means identifying trends early and incorporating requirements from missions, laboratory tests and field campaigns into our advisory work.

The developments observed in our conversation with DFKI highlight the growing importance of hi-rel components in modular robotic systems. They open new integration pathways and underscore the need for a precise understanding of power, data and material requirements in future mission architectures.

Further Information

- DFKI Robotics Innovation Center: https://robotik.dfki-bremen.de/

- DFKI Main Page: https://www.dfki.de/

- SherpaTT System Overview (DFKI): https://robotik.dfki-bremen.de/de/forschung/robotersysteme/sherpa-tt

- COYOTE III Overview: https://robotik.dfki-bremen.de/de/forschung/robotersysteme/coyote-iii/

Note for visitors: Our team will be on site at Booth F11, together with our partners 3D PLUS, Omnetics, and Exxelia.