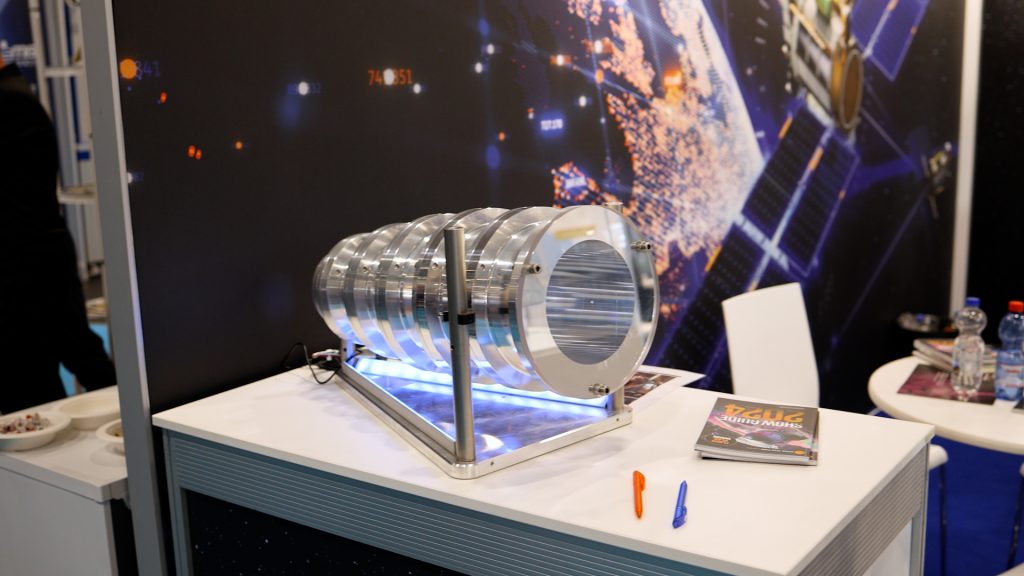

What looks like a play of light is, in fact, high-precision optics for orbit - the Winston Cone by TNO

Anyone who passed by TNO’s booth at Space Tech Expo Europe 2024 could hardly miss it. A flickering light, rhythmic and uniform, caught the attention of visitors - and that was exactly the point. Behind the seemingly simple light effect lies one of the understated yet critical components of modern space optics: the Winston Cone.

This specialized calibration unit is far more than a trade show gimmick. It represents a principle that plays a central role in satellite optics: uniform light distribution. Developed by the Dutch research institute TNO, the Winston Cone serves to create a homogeneous light source an essential prerequisite for the precise calibration of optical systems used in space missions.

Optical calibration - the key to precision

In space, calibration determines the quality of data. Every camera, spectrometer, and sensor system must know exactly how much light it receives and how that light is distributed. Even the smallest deviations can affect measurement accuracy - especially in missions focused on atmospheric data, Earth observation, or astronomy.

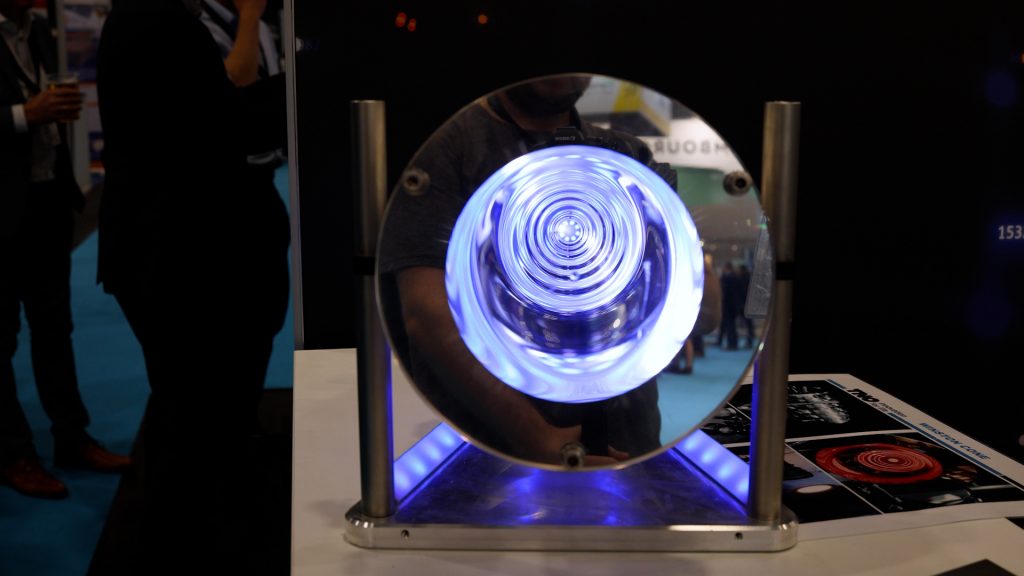

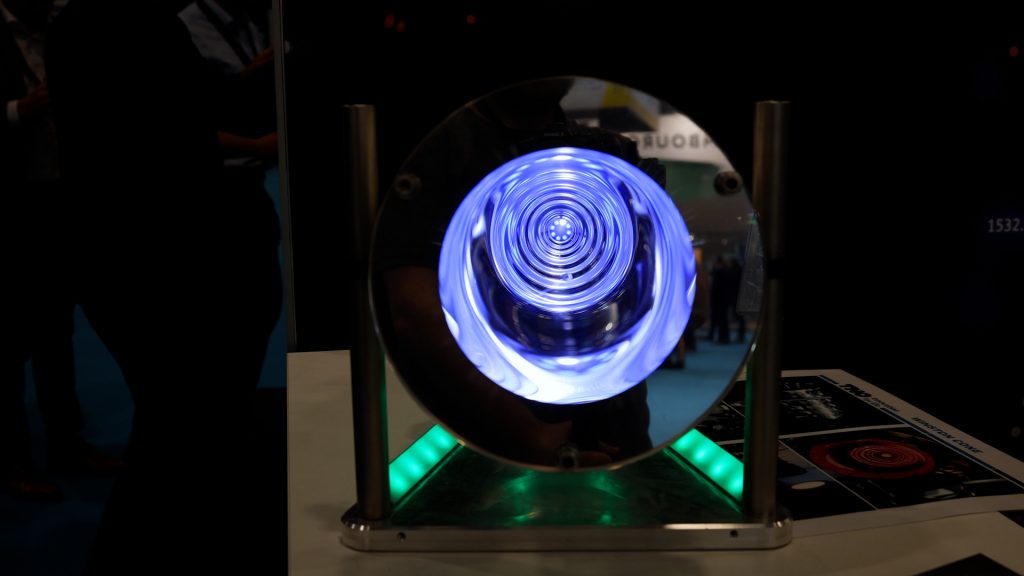

This is where the Winston Cone comes into play. Its parabolic interior geometry and defined entry and exit angles ensure that an injected light beam is distributed evenly. The result: a homogeneous light field that is ideal for calibration purposes. For engineers, this means stable and reproducible conditions for optical testing and system alignment.

“If you put a light source at the right focal plane, the outcome is uniform light,” explained Merijn Voets, Business Developer at TNO Space, during the exhibition. “We use this for space applications at TNO, and now we made some LEDs in it and some flickering. And everybody is attracted by this.”

What began as a scientific demonstrator turned into a true crowd magnet: a precise calibration device, creatively staged - and a symbol of how research, engineering, and communication intersect in the space industry.

From research to industry

TNO (Netherlands Organisation for Applied Scientific Research) is known for bridging the gap between fundamental research and industrial application. In the field of Space Systems, the institute develops optical and mechanical components for ESA missions and leading European aerospace companies. The goal: turning scientific findings into reliable space-qualified hardware.

The Winston Cone is a prime example. Originally conceived as a highly specialized light concentrator, it is now used in calibration systems for satellite instruments, where absolute light uniformity is essential. Such systems are applied to calibrate spectrometers and optical sensors onboard Earth observation satellites, ensuring long-term stability and accuracy.

European collaboration as a success factor

For MSA Components, TNO’s work is a familiar example of how European collaboration in the space sector succeeds: research institutes, technology developers, and specialized industrial partners co-create solutions that meet the extreme demands of space missions.

Optical calibration technologies developed by TNO and high-reliability electronic components supplied by MSA Components represent two sides of the same coin. Both rely on the highest levels of reliability, material integrity, and long-term stability - qualities that can define mission success in orbit.

Together, institutes like TNO and companies like MSA Components help ensure that Europe remains a leader in space engineering. From the development of optical systems to the qualification of electronic components, a strong network of expertise spans the entire value chain - from research to manufacturing.

When technology draws attention

What started as an eye-catcher at a trade fair is more than just a showpiece. The Winston Cone represents the connection between scientific precision and technical creativity.

That the installation at Space Tech Expo Europe 2024 drew many visitors is no surprise - the flickering LEDs were merely the visible part of a story about engineering excellence and the physics of light.

Or, as Merijn Voets put it: “Everybody is attracted by this.”

We certainly were - by the combination of optical refinement, technical clarity, and European collaboration.

Looking ahead to Part 2

In the second part of our TNO interview, André Hoogstrate, Senior Research Engineer in Optics Manufacturing, explains how research translates into tangible hardware. He provides insight into the Sentinel-5 mock-up – an optical payload designed to measure global air quality and atmospheric parameters.

Stay tuned - precision in research and manufacturing continues to be the connecting theme.

Visit us at the Space Tech Expo Europe 2025

As in previous years, we at MSA Components will be exhibiting at Space Tech Europe. We look forward to engaging with our customers and partners to discuss upcoming missions, qualification needs and custom solutions for next-generation spacecraft and the space industry. Please visit our stand to meet us in person and discuss your projects and challenges, and find out how MSA Components can support you with the latest technological innovations on the market.

You will find us at booth number F11.

Of course, you are welcome to schedule an appointment with us beforehand.