High temperature capacitors include :

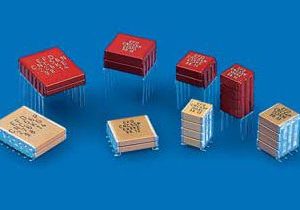

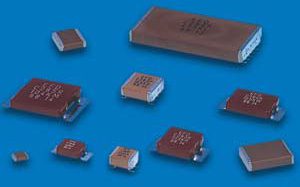

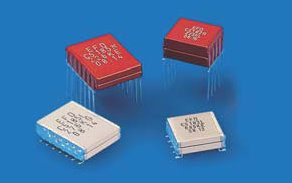

• chip class 1 (CEC 203 to CEC 233) and class 2 (CNC 203 to 233),

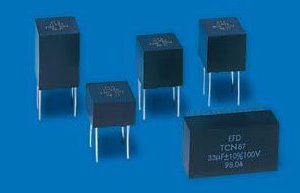

• encapsulated radial leads class 1 and 2 (TCE / TCN 201 to 204),

• encapsulated axial leads class 1 and 2 (TCE / TCN 252 to 254),

• selfprotected radial leads class 1 and 2 (TCE / TCN 212 to 216) and radial leads class 1 and 2 (TCE / TCN 263).

• high voltage varnished capacitors (TCH 279 to 285)

• high capacitance value CNC 253 to 255 (N for leaded and P for SMT).

• chip class 1 (CEC 203 to CEC 233) and class 2 (CNC 203 to 233),

• encapsulated radial leads class 1 and 2 (TCE / TCN 201 to 204),

• encapsulated axial leads class 1 and 2 (TCE / TCN 252 to 254),

• selfprotected radial leads class 1 and 2 (TCE / TCN 212 to 216) and radial leads class 1 and 2 (TCE / TCN 263).

• high voltage varnished capacitors (TCH 279 to 285)

• high capacitance value CNC 253 to 255 (N for leaded and P for SMT).

They are highly recommended for operation at temperatures of up to 200°C.

Capacitors specifically designed for higher operating temperatures (e.g. TCE / TCN 212 to 216 and TCE / TCN 263 to 266) are also available.

High temperature capacitors are made of class 1 or class 2 ceramic dielectrics featuring special compositions based upon high purity oxides to reduce ionic conduction inherent to the presence of atoms such as sodium.

In addition, all quality controls carried out at intermediate and final production stages (lot acceptance test under 0.5 URC and insulation resistance measurement at 200°C) are the assurance of enhanced reliability.

High temperature capacitors are made of class 1 or class 2 ceramic dielectrics featuring special compositions based upon high purity oxides to reduce ionic conduction inherent to the presence of atoms such as sodium.

In addition, all quality controls carried out at intermediate and final production stages (lot acceptance test under 0.5 URC and insulation resistance measurement at 200°C) are the assurance of enhanced reliability.